Sestriere Vernici for street furnishings, a worldwide presence.

COMPANY

Worldwide top leader in the production of stylish street furnishings such as: street lamps, benches, kiosks, plant racks, balustrades, public street lighting.

The acquisition is the result of the team work carried out with the customer during the last 2 years, with a significant technical and trading investment, which is rewarded by the trust the customer placed to us.

NEEDS

The operation’s particularity is due to the quite specific customer’s needs:

- Internal painting equipment with water system for at least 80% of the products used.

- External suppliers with solvent-based system but to be matched to a water-system, with clear matching problems between solvent finishing and water finishing. The issue was further complicated by the request of a matte finishing with maximum 1.5 gloss, metallised, with textured effect. The products can be applied with electrostatic or traditional systems.

- Resistance to saline mist on the complete package.

- Resistance to the test QUV test = 1000h with Δ% lower than 2 points.

- A first layer of hot dip 1k galvanised material to protect also hollow parts of cast iron housings composing the posts’ structure.

SOLUTION

The proposed cycle for the internal cast iron and steel plant with water system was carried out with the following products:

Internal cast iron and steel plant, water system

4001 Deeping, hot dip 1k galvanised material

3954 Aquaepox 2K

3978 Aquapur Casting Grey

The outside parties’ plant in aluminium and hot-dip galvanised steel with solvent system was built with the following products:

4970 Prime Coat FZ primer epoxy 2K

5001 Casting Grey

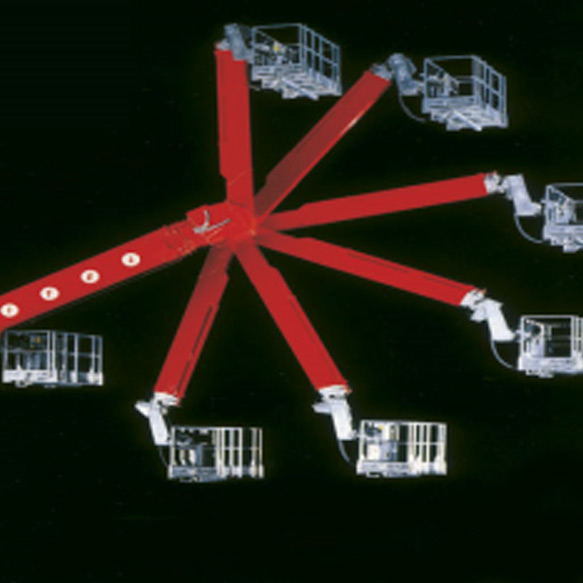

Facilities for works at heights: another excellence of Sestriere Vernici in a high-technological requirement industry

COMPANY

One of the leading companies in the production of equipment for works at height .

NEED

Paint the production platform in wet-on-wet cycles by using the same box for primer and enamel. The product built by the company is quite complex, with several undercuts, cylinders and hidden parts. It is therefore easy to immediately think about the overspray issue. Therefore a product that properly “wets” and reabsorbs its fumes will be necessary. On the other hand, however both primer and enamel must act fast: the former to allow its re-painting 20 minutes after the application and the latter to give the possibility of passing the products to the assembly step after 12 h and without the assistance of ovens and/or possibility of forced drying. Finally, the resulting product must have a brightness higher than 90 gloss!

SOLUTION

Eoxy primer 3955 NEW generation + enamel PUR 3970 Fast

The primer acts properly, by absorbing most of its fumes and its drying speed is unusually fast. After 20 minutes at a room temperature of 14°C, we managed to apply the finishing enamel.

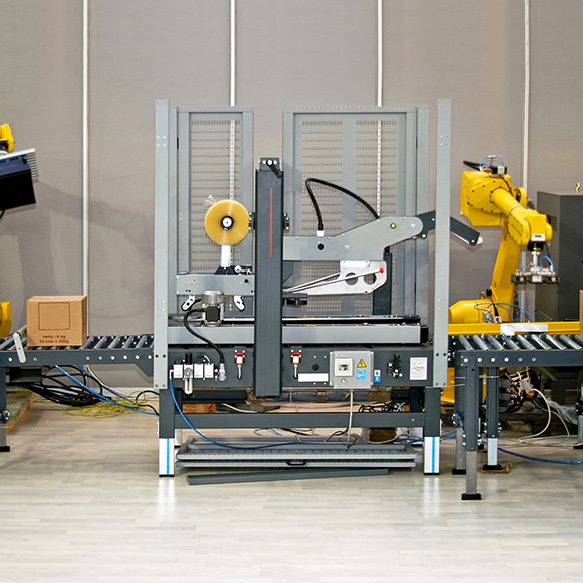

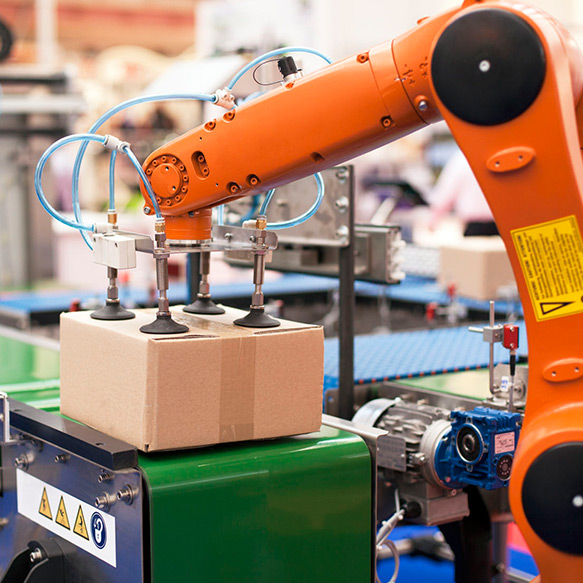

Sestriere Vernici for the world leading company in product packaging machineries

COMPANY

World leader in the planning and production of automatic machineries for the process and packaging of pharmaceutical products, cosmetics, food, tea and coffee.

NEED

Paint the frames for machine tools and the relevant components in wet-on-wet cycles, such components beings covers and equipment of packaging lines, by using a mixed primer SOV cycle + H2O finishing. The resulting products are quite complex, with trellis frames for machine tools, perforated and milled surfaces and hidden parts. It is therefore easy to immediately think about the overspray issue. Therefore a product that properly “wets” and reabsorbs its fumes will be necessary. The primer is still solvent-based, whereas the finishing is water-based in polished, semi-polished and metallised version. The primer must be fast enough to accept a wet-on-wet with water finishing, but also slow enough to absorb overspray.

SOLUTION

Epoxy primer 4970 Primer Coat FZ + enamel PUR

The primer acts properly, by absorbing most of its fumes and its drying speed is unusually fast. After 10 minutes at a room temperature of 17°C, we managed to apply the finishing enamel.

The enamel 3975 Silver Sparkle in aluminium is worthy of mention, which allowed us to win the challenge against a competitor due to its better brightness, distension and homogeneity of metallised effect.

The challenge was accepted and won by Sestriere Vernici, which was also supported by the just on time delivery and colorimetry work by the local reseller.

Sestriere Vernici for machineries producing non-woven fabrics in a high-complexity industry.

COMPANY

Present on the market for more than 70 years with high-range products and technological solutions for paper and non-woven fabrics.

NEED

Paint the frames for machine tools and the relevant components in wet-on-wet cycles which constitute equipment for the manufacturing of tissues and multi-purpose cloths.

The product built by the company is quite complex and large-sized, with steel machine basements weighing some tons, perforated and milled surfaces and hidden parts. Therefore weight is the main issue, which requires fast drying, also in depth, in order to move the part, avoid overspray shading and provide a polished and well projected surface. Therefore a product that properly “wets” and reabsorbs its fumes will be necessary, which must also promptly harden.

An epoxy primer will be used on a solvent-based cycle for outside parties, whereas acrylic will be used for the internal department.

The two plants and aesthetic results must be exactly the same because the parts will be assembled.

SOLUTION

The products that allowed to win the challenge:

epoxy primer 4950 Epofer + enamel PUR 5050, primer 3974 and enamel 3970 FAST.